Pulling out dent in rear panel

I now have most of the large body putty fills completed except one last dent in the rear panel underneath the bumper. I decided to try pulling the it out as much as possible first. [...]

Installing rear window

Today I installed the rear window. It was removed to weld in the driver side quarter panel that went up along the window and to weld in a new panel in between the trunk lid [...]

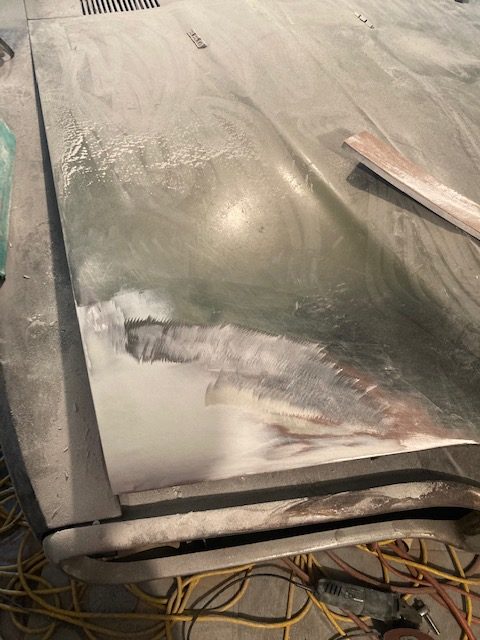

Finished sanding patch + primed on hood and front fender

Another layer of body putty was added and sanded down with the long flexible sanding block. On the hood, I also realized I built up the bend too much and was sticking a little higher [...]

Finished dent in rear quarter panel and primed

Today I continued sanding and reapplying body putty fills on the hood corner and large front driver side fender. These large fills should be finalized this week. Meanwhile, the small dent in the rear quarter [...]

Still subtle ripple on patch on front hood so it was widened

The patch that was on the hood was shaping up well but I still felt a subtle wave above the fill. So I sanded off a wider part of the hood and proceeded to fill [...]

Finished wheel well patch + primed

I initially was sanding the wheel well body fill patches by molding the sandpaper over my finger but it was still creating waves. So I thought of using a long glue stick or tubing to [...]

Priming the driver side front quarter panel body fill

Here I finished up the front ding that was filled with body filler and sanded. The ding was on the driver side front quarter panel under the firebird logos I sprayed it with self etching [...]

Body putty fill around wheel well groove

I noticed there were very small pits on the body around the driver side wheel well fender from rust. If you install the factory chrome wheel well trim, it might cover it. However I do [...]

Body putty over hood + reworking front fender

As you can see, I have any possible rust painted with rust oleum and then eventually filled roughly . Plus I updated the fender with more coats of filler.

Started body filling in lower panel and finishing up rear quarter panels

Here I put a few coats of body putty over the driver side lower panel under the door. Then finally finished up the rear quarter panels by sanding with finer grit sandpaper and priming